- Satara - 415109, Maharashtra, India.

- response@mahekaralcastings.com

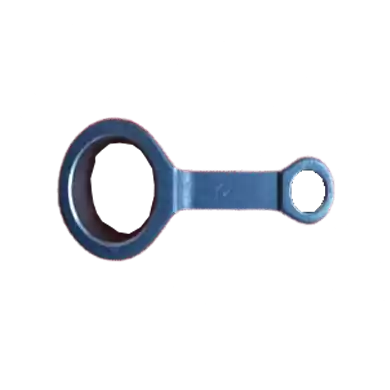

Sintered Connecting Rods Manufacturer

Mahekar Engineers, an ISO 9001:2015 Certified Company by TUV, Austria, located near Pune, specializes in the Manufacturing and Supply of Aluminium Rods, Extrusion Rods, Split Rods and various categories of Aluminium Pressure Die Casting services including High Pressure, Low Pressure and Gravity Die Castings.

With over 30 years of extensive experience, we strive to be a leading supplier in our industry. Our highly skilled team, with deep expertise in the field, upholds the highest manufacturing standards using advanced machinery and equipment.

Sintered rods are a critical innovation in the field of engineering, particularly for companies involved in manufacturing and exporting casting products. These rods are created through the sintering process which involves compacting metallic powders into a desired shape and then subjecting them to high temperatures below the melting point of the base metal. This process results in a dense, durable component with excellent dimensional precision and micro porosity, making it suitable for various industrial applications. The raw materials for sintered rods typically include pure metals like iron or copper or alloyed powders such as bronze or steel which are carefully selected based on the desired mechanical properties.

The production process begins with mixing metal powders with alloying elements and lubricants to ensure uniformity and consistency. The mixture is then compacted under high pressure using precision tooling to form a green part, which has sufficient mechanical strength for handling. This green part undergoes sintering in controlled atmospheres and specific temperatures, where solid state diffusion fuses the particles together, creating a robust structure. Post sintering operations like heat treatment, machining or surface finishing can further enhance the properties of the rods such as hardness, wear resistance or dimensional accuracy.

- High Precision and Uniformity: Sintered rods offer precise dimensional control and uniformity, ensuring consistent performance across applications. This precision reduces the need for post processing and enhances overall product quality.

- Enhanced Mechanical Properties: These tools exhibit improved mechanical properties such as strength, toughness and resistance to wear ,making them suitable for demanding industrial environments.

- Cost Effective Production: The sintering process allows for efficient production with minimal material waste, reducing costs compared to traditional machining methods.

- Simplified Standards: The high precision of these rods often eliminates the need for extensive machining, saving time and resources in the production process.

- Optimized Thermal Performance : Certain sintered rods, especially those made from metals like copper or aluminum, exhibit high thermal conductivity, making them ideal for applications requiring efficient heat transfer.

- Oxidation Resistance: Sintered rods can be produced with coatings or materials that provide excellent oxidation resistance, extending their lifespan in harsh environments.

- Sturdy Construction: These tools can be engineered to be lightweight while maintaining high strength which is advantageous in applications where weight reduction is critical.

- High Temperature Furnaces: Sintered rods such as molybdenum or silicon carbide rods are used as heating elements or structural supports in high temperature furnaces for industries like metallurgy, ceramics and glass.

- Molten Metal Processing: These rods are employed in metal smelting and processing as agitators, crucibles or liners due to their ability to withstand extreme temperatures.

- Vacuum Electronic Devices: Sintered rods serve as key components like anodes and cathodes in vacuum electronic devices, ensuring stable electron emission and conduction in high temperature environments.

- Chemical Engineering: In chemical engineering, these devices act as catalyst carriers , maintaining stability at high temperatures to promote catalytic reactions and improve product yield.

- Automotive Components: Sintered rods are used in automotive applications such as connecting rods, engine parts and transmission systems due to their strength and wear resistance.

- Scientific Research Equipment: These rods are applied in experimental furnaces and testing equipment for high temperature analysis in scientific research.

- Sustainable Power Generation: These tools are used in wind turbines and solar trackers for precise mechanical functions under demanding conditions.

Get Your Quote Now!