- Satara - 415109, Maharashtra, India.

- response@mahekaralcastings.com

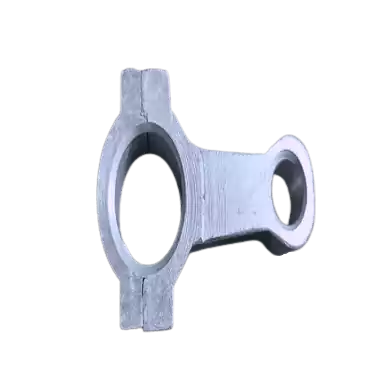

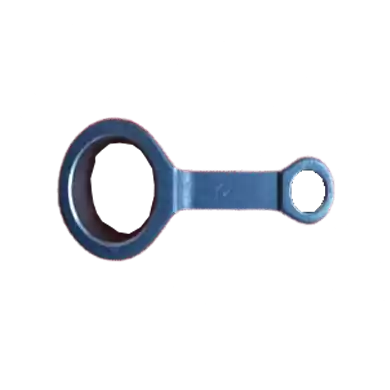

Connecting Rods Manufacturer

Mahekar Engineers stands as a prominent name in the engineering industry,for over a substantial period of 30 years and more, specializing in the manufacturing and export of premium quality Connecting Rods. Our diverse product portfolio includes Aluminum Pressure Die-Cast Connecting Rods, Sintered Connecting Rods, Split Type Connecting Rods, Aluminum Bearings and other related components. With a strong foundation as a leading manufacturer and supplier, we have established a significant presence in the industry. Committed to excellence and global standards,we are an ISO 9001:2015 Certified Company by TUV, Austria, we consistently deliver high quality Connecting Rods.

Connecting rods are critical components in various machinery, particularly in internal combustion engines where they play a pivotal role in converting linear motion into rotational motion. In an engineering company that specializes in manufacturing and exporting casting products such as aluminum rods, extrusion rods and sintered rods the connecting rod serves as a prime example of precision engineering and material application. Typically made from high strength materials, connecting rods are designed to withstand the intense forces generated during engine operation. The design and manufacturing of these rods involve a careful selection of materials and processes, ensuring they can handle the stress and fatigue encountered in dynamic environments.

Aluminum, known for its featherweight and strength characteristics, is often used in the fabrication of connecting rods, especially in applications where reducing weight is critical for improving engine efficiency and performance. The extrusion process allows for the creation of complex shapes and profiles, providing the necessary strength to weight ratio while minimizing material waste. Sintered rods, made through powder metallurgy, offer enhanced mechanical properties and can be tailored to specific applications by adjusting the composition of the materials used. In the context of a technical and mechanical company, understanding the shape analysis of connecting rod design is essential, as these components must meet rigorous standards for quality and performance. The manufacturing process typically involves precision machining, heat treatment and surface finishing to ensure that the connecting rods meet the strict tolerances required for optimal performance.

- Improved Engine Efficiency: Connecting rods improve the efficiency of power transmission in engines, enabling higher output and better acceleration for varied machinery.

- Weight Optimization: By utilizing light materials and optimized designs, connecting rods contribute to weight reduction which enhances performance.

- Enhanced Longevity: High quality connecting rods are engineered to withstand extreme conditions, leading to longer service life and reduced maintenance costs for different companies.

- Precise Fabrication: Advanced manufacturing techniques ensure that connecting rods are produced with high precision which enhances the reliability of the entire engine system.

- Customization Capabilities: Engineering companies can tailor connecting rods to meet specific client requirements, allowing for customization in various applications across different industries.

- Vibration Control: Well designed connecting rods help minimize engine vibrations, leading to smooth operation and enhanced ease for users of distinct machinery.

- Automobile Power Units: Connecting rods are primarily used in internal combustion engines where they convert the linear motion of pistons into rotational motion for power generation.

- Motorcycles: In motorcycles, connecting rods play a crucial role in engine performance, enabling efficient power delivery and contributing to the lightweight design.

- Aircraft Engineering Solutions: These devices are utilized in aircraft engines, where they must withstand extreme conditions while ensuring reliable operations and safety during flight.

- Power Machinery: In construction and agricultural equipment, these rods facilitate the operation of large engines, ensuring strength and efficient power transfer in demanding environments.

- Generators: Connecting rods are found in generators where they help convert mechanical energy into electrical energy, supporting various industries relying on power generation.

- Industrial Equipment: In various industrial machinery, these devices contribute to the efficient functioning of engines that drive processes, enhancing productivity in manufacturing.

Get Your Quote Now!