- Satara - 415109, Maharashtra, India.

- response@mahekaralcastings.com

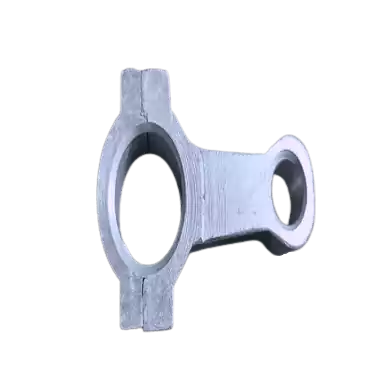

Extrusion Connecting Rods Manufacturer

Mahekar Engineers is an eminent manufacturer and exporter of Connecting Rods, Aluminium Rods, Extrusion Rods and a successful provider of high pressure, low pressure and gravity die casting services for a period more than 30 years. Backed by a modern infrastructure and a team of skilled professionals, we efficiently cater to diverse customer requirements.

Located near Pune, at Taswade Karad Industrial area , we are an ISO 9001:2015 Certified Company by TUV, Austria, dedicated to innovation in manufacturing high quality products. Our commitment to industry advancement enables us to consistently deliver superior products while upholding a strong market reputation.

Extrusion rods play a vital role in the operations of technical companies involved in the fabrication and supply of casting products. These rods are created through the extrusion process where a metal billet is forced through a die to produce rods with exact cross sectional shapes. Extrusion rods are essential for various applications in engineering industries due to their ability to deliver uniformity, consistent quality and adaptability to different specifications. Major technical companies rely on extrusion rods for producing components that require exactness and endurance, ensuring that the final cast products meet engineering guidelines and quality benchmarks.

These rods are typically manufactured from materials like aluminium, copper and other alloys which offer excellent compatibility with diverse casting techniques such as sand casting, die casting and investment casting. Industrial companies specializing in casting products benefit from the ability to export extrusion rods as semi-finished goods for global clients. This develops businesses to cater to the growing demand for high quality and customizable raw materials in various markets. Extrusion rods are often supplied in different sizes, shapes and finishes, enabling companies to meet the needs of a wide range of industries. The precision offered by extrusion rods helps in reducing material wastage during production, ultimately contributing to low budget in large scale manufacturing operations.

Additionally, extrusion rods are crucial in the development of prototypes and the production of specialized parts for engineering projects. Their consistent mechanical properties and ability to undergo secondary processes like welding and coating make them indispensable for creating reliable casting products.

- Flexible Specifications: Extrusion rods can be manufactured in a variety of shapes and sizes, allowing engineering companies to meet specific project requirements with precision.

- Precise Measurements: The extrusion process ensures that rods have consistent and accurate dimensions which is crucial for producing reliable and high quality engineering products.

- Improved Structural Integrity: Extrusion rods offer superior mechanical properties, The process improves the grain alignment, resulting in superior strength and durability.

- Adjustability: They are available in materials like aluminium, copper and alloys, providing versatility for industries with diverse needs such as automotive, aerospace and construction.

- Optimized Production Process: Using extrusion rods simplifies manufacturing processes, reducing production time and material waste for technical companies.

- Economical Solution: Extrusion rods are produced in bulk and with minimal material loss, offering a cost efficient raw material for mass production.

- Harmonization: Extrusion rods can be easily processed through various casting methods such as die casting and investment casting, ensuring seamless integration into production lines.

- Rust Proof: Extrusion rods, especially those made from aluminium, have excellent resistance to corrosion, making them ideal for harsh environments.

- Enhanced Machining: They are easy to drill and weld, enabling industrial companies to create complex designs and components effortlessly.

- Automotive Industry: Extrusion rods are used for engine components, structural parts and frames due to their lightweight and strong properties, improving vehicle efficiency.

- Space Technology Industry: They are used in manufacturing aircraft parts such as fuselage frames, wing supports, and landing gear because of their strength-to-weight ratio.

- Structural Engineering Industry: Extrusion rods are utilized for building frameworks, railings and window frames, offering durability and corrosion resistance in structural applications.

- Electrical Applications: Copper and aluminium extrusion rods are used in power transmission lines and electrical connectors due to their excellent conductivity.

- Sustainable Power Solutions: Extrusion rods are used in solar panel frames and wind turbine components, offering solutions for energy efficient systems.

- Fabrication Systems: Extrusion rods are vital for producing machine parts, tools and industrial equipment because of their durability.

- Packaging Industry: They are used in creating aluminium foils, beverage cans and other packaging materials, offering sustainability and recyclability.

Get Your Quote Now!